Hydraulic Jacking Equipment

Description

Hydraulic jacking equipment is a lifting equipment mainly used for lifting installation of all kinds of large storage tank, gas holder, desulfurization tower in power plants, steel structure, etc.

Features

1. This hydraulic lifting equipment is designed with all kinds of hydraulic valves that control the lifting operation.

2. Control system of this hydraulic jacking equipment includes the console, pump controller, inductor and connecting cables. It controls the whole system by receiving information and instructions from the sensor.

3. Our hydraulic lifting equipment is designed with feed-through structure, so the steel wire can be inserted through the center of the jack.

4. The upper and lower clamping devices are integrated with this lifting jack, and its top is connected with steel wire through using claw plate.

5. The hanging piece is connected with the steel wire through component clamping device.

Forging Excellence, Welding Solutions!

- E-mail:eric@weldc.com

- WA :+86 150 0619 3977

- YouTube :https://www.youtube.com/@ericxu1146

Description

Application

Hydraulic jacking equipment is installed in the absorption tower on the ground. It can carry out operations include coiling, welding, butt jointing, reinforcement welding and lifting to avoid safety issues presented by high-altitude operations in the construction and operation process.

Advantages

1. This hydraulic lifting equipment is a set of lifting machine that integrates hydraulic, electrical and control technology.

2. Our hydraulic jacking equipment is capable of carrying out vertical lifting and placement of large and heavy pieces in difficult operating conditions.

3. It is characterized by small volume, light weight, heavy capacity, easy installation, high degree of automation, simple and safe to operate, and reliable performance.

4. It lifts tank through hydraulic pressure.

5. This lifting jack can ensure safety in case of a sudden power failure or fracture.

6. Tanks can be stably lifted up along the track.

Technical Parameters of Hydraulic Jacking Equipment

| Model | ABK-JS25 | ABK-JS35 | ABK-JS50 | ABK-JS100 |

| Working capacity (metric ton) | 16 | 23 | 33 | 66 |

| Testing load (metric ton) | 25 | 35 | 50 | 100 |

| Standard arc spacing between jacks (m) | 2-4 | |||

| Trestles lift plates up to (m) | 2.6 or more | |||

| Min. plate (m) | 0.10 | |||

| Plate thickness range (mm) | 5 and abpve | |||

| Climb (cm/stroke) | 10 | |||

| Time per stroke (second) | 50-80 | |||

| Piston retracting system | Spring | |||

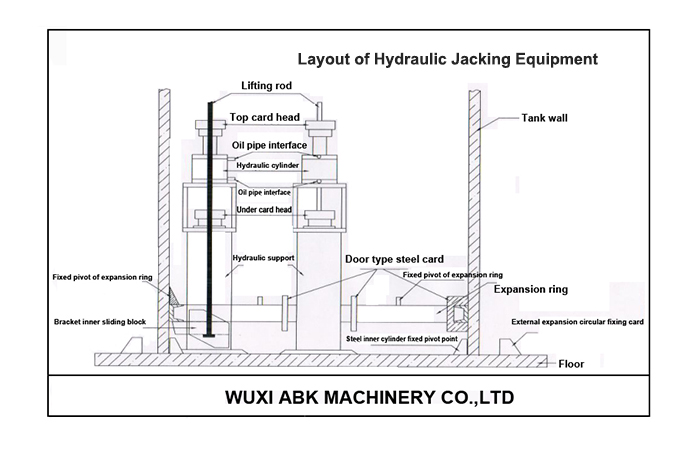

Layout of Hydraulic Jacking Equipment