-

Description

Our BYGG series portable shot blasting machine is an advanced shot blasting equipment in both domestic and overseas markets. This mobile shot blaster features environmental protection, energy saving, high efficiency, free of dust and low noise. It only needs one operator, saving labor cost. It is suitable for cleaning tanks for petrochemical and shipbuilding industries, wind power tower, etc.

Working Principle

Abrasive media are lifted to the drum sieve by the bucket elevator. The drum sieve has inside and outside spiral blades. Inside blades can discharge large pieces of mixture; abrasive, sand and dust are sieved, pushed and then fully separated by outside blades.

-

Description

Hydraulic jacking equipment is a lifting equipment mainly used for lifting installation of all kinds of large storage tank, gas holder, desulfurization tower in power plants, steel structure, etc.

Features

1. This hydraulic lifting equipment is designed with all kinds of hydraulic valves that control the lifting operation.

2. Control system of this hydraulic jacking equipment includes the console, pump controller, inductor and connecting cables. It controls the whole system by receiving information and instructions from the sensor.

3. Our hydraulic lifting equipment is designed with feed-through structure, so the steel wire can be inserted through the center of the jack.

4. The upper and lower clamping devices are integrated with this lifting jack, and its top is connected with steel wire through using claw plate.

5. The hanging piece is connected with the steel wire through component clamping device.

-

Description

CSAW-1000 submerged arc welding tractor is mainly used for welding flat or corner joints and the cylinder of tank. This automatic submerged arc welding machine is applicable for welding longitudinal seams of cylinder with a diameter larger than 800mm. Tractors with different configurations are available.

Features

1. This submerged arc welding tractor is self-propelled for butt and fillet joints on lengthy welding applications.

2. Stable and unique three- or four-wheel design.

3. Walking worm drive with clutch.

4. Flexible system allows set up with or without a track.

5. This automatic submerged arc welding machine is equipped with Miller welding system.

6. Infrared laser sight facilitates welding alignment.

7. Wire diameter range: 2.4mm – 4.8mm.

-

Description

MAGW-I LNG/LPG tank vertical welder is designed to weld vertical seam of special materials (such as stainless steel, 5% Ni steel and 9% Ni steel). It is equipped with a MAG/MIG welding system. Our vertical tank welding machine features high efficiency, X-ray weld seam and low heat input.

-

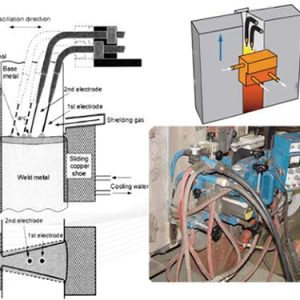

Description

TEGW two-electrode electrogas welder is designed for welding thick plates requiring high heat input. This electrogas welding machine is widely used to weld sheer strakes and hatch side coamings of container ships.

-

Electrogas welding machine (EGW) is a highly-efficient automatic welding equipment manufactured to realize closed-loop weld current. It is designed with optional ways of mounting, including permanent magnet adsorption, electro magnet adsorption, vacuum absorption with a vacuum sucker, switch permanent magnet adsorption, making it convenient to assembly and disassembly. This electrogas welding machine is widely used for welding of thick plates in industries like oil, chemical, blast furnace, shipbuilding, etc.

Features

1. The liquid level of the molten pool can be automatically controlled.

2. Wire extension can be automatically adjusted.

3. The travel carriage is small in size, light in weight, as well as flexible and convenient to use.

4. Modular design of this vertical electrogas welder facilitates upgrade of the machine.

5. Welds of this electrogas welding machine are done in single pass, no inter-pass cleaning.

6. Welding plate thickness: 10mm~50mm.