Automatic Girth Welder

WUXI ABK provides submerged arc welding machine used for vertical cylinder construction. Different from the current market, our MSHW series automatic girth welder is equipped with a stable dual drive system. The self-propelled submerged arc welding system can help reduce the constructions time to 25% of the manual welding. The transverse welding machine is used for welding the inner and outer ring of the vertical cylinder. We offer automatic girth welders with 3 configurations for various types of tanks.

Forging Excellence, Welding Solutions!

- E-mail:eric@weldc.com

- WA :+86 150 0619 3977

- YouTube :https://www.youtube.com/@ericxu1146

Description

Main Parts of Automatic Girth Welder

A. Operator Platform

| Description | Its main frame is composed of transeverse operation unit and welded steel structure |

| Applicable for “bottom up” tank erection | |

| Min. Dia.:5.0m | |

| Shell plate : 1.5m~2.5m | |

B. Dual Drive Unit

AC double drive design allows this submerged arc welding machine to make a full circle around the tank and weld all the defects and flaws while it’s moving. This dual drive system is more stable and easier to use compared to single drive system, and it’s more efficient in repairing defects.

Programmable variable frequency drive

C. Power Source and Wire Feeder

| Description | The welding system is equipped with LINCOLN NA-3 control and wire feeder, as well as the corresponding wire spool and wire reels. It accommodates coils of submerged arc welding wires below 27.2kg. |

| Power Source | LINCOLN DC600 |

| United States NA-3S control box | |

| United States NA-3 wire feeder | |

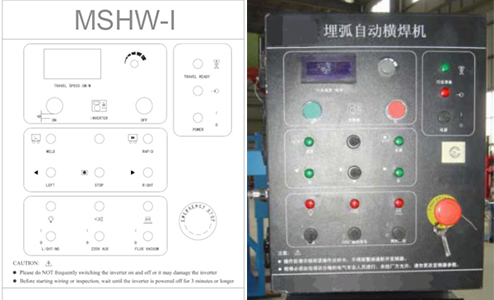

D. Controller

AGW control system is a comprehensive control box that controls the operation of automatic girth welder. It can control flux recovery vacuum pump, 220V socket switch, auxiliary power, etc. The control box consists of the required digital display, knobs, switches, indicator lights and emergency stop buttons, etc.

E. Flux Recovery System

Capacity: 60kg

F. Cable

| Welding Cable | 120mm2×60m |

| Control Cable | 10p×2.5mm2×60m |

| Power Cable | 3p×4mm2×60m |

| Grounding Cable | 120mm2×5m |

G. Cabinet

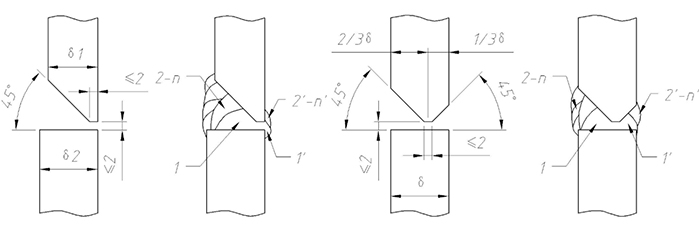

H. Type of Groove

Thickness ≤14mm Thickness>14mm

Components of GSAW-600 Automatic Girth Welder

| NO. | Components | Manufacturer | Quantity | Remark | |

| 1 | Main Machine | NA-3 wire feeder | USA LINCOLN | 1set | Imported |

| Wire reel and wire spool | |||||

| Torch and angle trimmer | |||||

| Wire straightener | |||||

| 2 | Operation Box and Control Panel | NA-3 control | |||

| Control box for rack travel (control panel included) | WUXI ABK | 1set | China | ||

| 3 | Power Source | LINCOLN DC600 | USA LINCOLN | 1set | Imported |

| 4 | Travel Carriage | AC motor (2 sets) | WUXI ABK | 1set | China |

| Cross beam | |||||

| Drive wheel assembly (2 sets) | |||||

| Aluminum / wind-shielding welding frame | |||||

| Operator platform | |||||

| Travel carriage frame and its adjusting mechanism (2 sets) | |||||

| 5 | Torch Adjusting Device | Adjusting mechanism of torch | 1set | ||

| 6 | Automatic Flux Recirculating System | Flux support system assembly | 1set | ||

| Flux support belt tightening device | |||||

| Flux transport and recovery kit | |||||

| Flux supply container | |||||

| Vacuum pump | |||||

| 7 | Auxiliary System | Control panel of power distribution system | 1set | ||

| Explosion-proof lighting lamp | |||||

| 8 | Cable assembly | Control cable (120mm2 × 60m × 1) | High-quality outlet cable for tank welding machine | 1set | |

| Control cable (10p × 1.5 mm2 × 60m × 1) | |||||

| Power cable (3p × 4mm2 × 60m × 1) | |||||

| Grounding cable (120mm2 × 5m × 1) | |||||

| 9 | Power Supply and Cable Storage Box | Rack and power supply distribution control cabinet | WUXI ABK | 1set | Rainproof |

| Welding power source and cable | |||||

| 10 | Tools | Tool kit and tool sets | 1set | China | |

(GSAW-600 inverted submerged arc welding machine requires 380V+10%/3PH/50Hz, and it is used for bottom-up tanks.)