Showing 1–20 of 21 results

-

Description of Wind Tower Welding Line:

This wind tower welding line, also called wind turbine tower production line, is specially designed for the submerged-arc welding of outer circular seam of wind power generator tower pole. It adopts cantilever structure, and can use several single cantilever structures to make up a welding workstation so that it can do multi-pass welding. In this way, its welding efficiency can be greatly increased.

This wind tower welding line is mainly composed of bending machine (rolling machine), CNC cutting machine, welding equipment, welding rotator set, and sandblasting and painting turning rolls.

-

Complete welding operation efficiently: choose the best welding operation frame.

-

This adjustable welding rotator is designed and manufactured to better meet increasing demands for pressure vessel manufacturers, so it enjoys more advantages over other similar products at home and abroad….

-

Technical Parameters of Standard Welding Rotator: Description of Standard Welding Rotator: Our standard welding rotator is mainly used for handling and automatic welding circular metal containers, and can be widely…

-

Established in 1999, Wuxi ABK Machinery Co.Ltd is a professional manufacturer of various welding rotators in China. And our welding rotators includes standard welding rotator, adjustable welding rotator, and various…

-

Features of Welding Positioner: 1. Our welding positioner has employed frequency conversion speed regulation system to change its running speed. 2. The stepless speed regulation is adopted to make this…

-

Features of Welding Turntable: 1. There are six T-shaped slots on the worktable in order to fix workpieces tightly. 2. Six stiffeners are welded on the rear side, thus the…

-

INTRODUCTION 1. Plasma Transfered Arc Welding Machine a) Equipment definition: free type 4-axis industrial control movement mechanism. b) Quality grade: plasma fusion welding c) Equipment model: PTA-ABK-400L. d) Equipment principle:…

-

It is used for automatic welding of circular pipe ring. The design, manufacture, installation and commissioning of the equipment shall be delivered to Party B after the equipment acceptance is qualified. After friendly consultation between the two sides, the technical proposal is as follows.

-

As commonly seen with superheaters, economizers, reheaters and others are made up of long lengths of tubes. The tube to tube welding machine facilitates the joining of tubes by gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW) or both. Our equipment meets the stringent requirement of the boiler manufacturing industry.

Take away the methods of yesterday whereby lengths of tubes or elbows are joint manually. The tube to tube welding machine is a high efficiency, quality and consistency production equipment. The secret lies in the combinations of the pulsed TIG method, hot wire system, AVC and proprietary program developed by us.

-

The standard membrane panel welder is designed to a width of 1600mm operating with 4 welding torches utilising submerged arc welding (SAW) technology. This is the most commonly ordered specification for good reasons:

– High productivity/efficiency in fabrication

– Panel products within transportation limits

– Practical and stable application

– Lower cost of machine and meeting sufficiency

We may however custom built to the customer’s requirement (owing to technical limitations). Our experiences span from panel welders with varying widths, number of welding heads , SAW or MIG/MAG or both utilizing your preferred power sources.

-

Description

Our BYGG series portable shot blasting machine is an advanced shot blasting equipment in both domestic and overseas markets. This mobile shot blaster features environmental protection, energy saving, high efficiency, free of dust and low noise. It only needs one operator, saving labor cost. It is suitable for cleaning tanks for petrochemical and shipbuilding industries, wind power tower, etc.

Working Principle

Abrasive media are lifted to the drum sieve by the bucket elevator. The drum sieve has inside and outside spiral blades. Inside blades can discharge large pieces of mixture; abrasive, sand and dust are sieved, pushed and then fully separated by outside blades.

-

Description

Hydraulic jacking equipment is a lifting equipment mainly used for lifting installation of all kinds of large storage tank, gas holder, desulfurization tower in power plants, steel structure, etc.

Features

1. This hydraulic lifting equipment is designed with all kinds of hydraulic valves that control the lifting operation.

2. Control system of this hydraulic jacking equipment includes the console, pump controller, inductor and connecting cables. It controls the whole system by receiving information and instructions from the sensor.

3. Our hydraulic lifting equipment is designed with feed-through structure, so the steel wire can be inserted through the center of the jack.

4. The upper and lower clamping devices are integrated with this lifting jack, and its top is connected with steel wire through using claw plate.

5. The hanging piece is connected with the steel wire through component clamping device.

-

Description

CSAW-1000 submerged arc welding tractor is mainly used for welding flat or corner joints and the cylinder of tank. This automatic submerged arc welding machine is applicable for welding longitudinal seams of cylinder with a diameter larger than 800mm. Tractors with different configurations are available.

Features

1. This submerged arc welding tractor is self-propelled for butt and fillet joints on lengthy welding applications.

2. Stable and unique three- or four-wheel design.

3. Walking worm drive with clutch.

4. Flexible system allows set up with or without a track.

5. This automatic submerged arc welding machine is equipped with Miller welding system.

6. Infrared laser sight facilitates welding alignment.

7. Wire diameter range: 2.4mm – 4.8mm.

-

Description

MAGW-I LNG/LPG tank vertical welder is designed to weld vertical seam of special materials (such as stainless steel, 5% Ni steel and 9% Ni steel). It is equipped with a MAG/MIG welding system. Our vertical tank welding machine features high efficiency, X-ray weld seam and low heat input.

-

Description

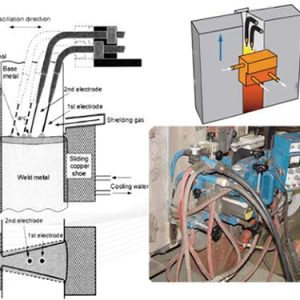

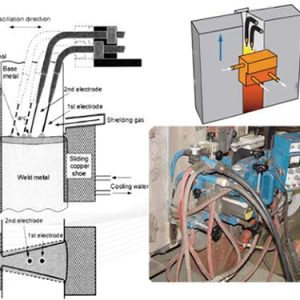

TEGW two-electrode electrogas welder is designed for welding thick plates requiring high heat input. This electrogas welding machine is widely used to weld sheer strakes and hatch side coamings of container ships.

-

Electrogas welding machine (EGW) is a highly-efficient automatic welding equipment manufactured to realize closed-loop weld current. It is designed with optional ways of mounting, including permanent magnet adsorption, electro magnet adsorption, vacuum absorption with a vacuum sucker, switch permanent magnet adsorption, making it convenient to assembly and disassembly. This electrogas welding machine is widely used for welding of thick plates in industries like oil, chemical, blast furnace, shipbuilding, etc.

Features

1. The liquid level of the molten pool can be automatically controlled.

2. Wire extension can be automatically adjusted.

3. The travel carriage is small in size, light in weight, as well as flexible and convenient to use.

4. Modular design of this vertical electrogas welder facilitates upgrade of the machine.

5. Welds of this electrogas welding machine are done in single pass, no inter-pass cleaning.

6. Welding plate thickness: 10mm~50mm.

-

WUXI ABK provides submerged arc welding machine used for vertical cylinder construction. Different from the current market, our MSHW series automatic girth welder is equipped with a stable dual drive system. The self-propelled submerged arc welding system can help reduce the constructions time to 25% of the manual welding. The transverse welding machine is used for welding the inner and outer ring of the vertical cylinder. We offer automatic girth welders with 3 configurations for various types of tanks.

-

By absorbing merits of similar Gantry Welding Machine and using new technology from abroad and China domestic, Wuxi ABK is the professional producer to develop and manufacture the family Gantry Welding Machine products including H-beam (light steel, heavy steel), T-beam welding production line, H-beam flange straightening machine, and steel structure cold roll forming production line as well as CNC waterjet cutting machine. With years development, ABK Gantry Welding Machine have been spread over Saudi Arabia, Russia, Middle Asian, Southeast Asian, Australia, Europe, South American, North American, etc. Look forward to establishing mutually beneficial cooperation.

-

H-beam assembly machine is a kind of equipment specially used for H-beam assembly, which completes the assembly requirements of various types of H-beams through automation. It can greatly improve the production efficiency and product quality, reduce the waste of manpower, optimize the production process, and make the complex assembly task of H-beam members simple and easy, so it is one of the essential and important equipment in modern production.