Tube To Tube Welding Machine

As commonly seen with superheaters, economizers, reheaters and others are made up of long lengths of tubes. The tube to tube welding machine facilitates the joining of tubes by gas tungsten arc welding (GTAW) or gas metal arc welding (GMAW) or both. Our equipment meets the stringent requirement of the boiler manufacturing industry.

Take away the methods of yesterday whereby lengths of tubes or elbows are joint manually. The tube to tube welding machine is a high efficiency, quality and consistency production equipment. The secret lies in the combinations of the pulsed TIG method, hot wire system, AVC and proprietary program developed by us.

Forging Excellence, Welding Solutions!

- E-mail:eric@weldc.com

- WA :+86 150 0619 3977

- YouTube :https://www.youtube.com/@ericxu1146

Description

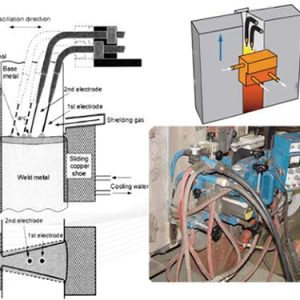

1) Hot wire system

The system produces a true sine-wave output, resulting in a stable and consistent welding arc. The AC waveform ensures no magnetic effect with the DC welding arc. It’s benefits:

- High deposition rate

- High welding speed

- Low risk of lack of fusion

- Highly suitable for narrow-gap welding and surfacing

2) Arc Voltage Control (AVC)

TIG arc as a sensor for gathering distance information. The arc voltage and position adjustment to keep the torch height above the melt pool by compensation of the deviations in arc voltage with regard to the reference value using mechanical height adjustment.

3) Program

Our proprietary program had undergone many evolutions and improvements. Today, it allows for an extensive setting of parameters at various instances that would correct undesirable moments in weld formation.

Overview of Specifications:

Tube Diameter: 28-76mm

Wall Thickness: 1.5-20mm

Wire Size: 0.8-1.0mm

Oscillation Range / Speed: 0-20mm / 0-120mm/s

Wire heater: 5-100 A