Horizontal Tank Welder

Description:

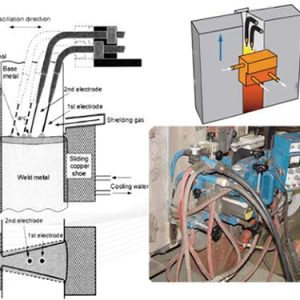

KA-H10 horizontal tank welder is a welding equipment is used to drive the gear rack and pinion, which is widely used in horizontal and vertical butt welding. It is especially suitable for medium and heavy plate welding and large pipe girth welding.

By adjusting the welding torch position and angle, it can also be welding, horizontal welding, overhead welding and arc welding.The trolley body, swinging device and control panel are separated, which can be welded on the track. It is convenient to install and remove the rail with a strong magnet on the workpiece.

Forging Excellence, Welding Solutions!

- E-mail:eric@weldc.com

- WA :+86 150 0619 3977

- YouTube :https://www.youtube.com/@ericxu1146

Description

Application:

CO2 automatic welding trolley is widely used in ships, bridges, locomotives, steel structure, oil and chemical industry, which is suitable for various welding structure of welding, such as stiffened plate, floor, cross site welding, box girder welding, etc.

It is used for rule of the vertical butt welding, butt weld, which can also suitable for horizontal position welding and fillet welding through adjustment of the welding torch position and angle.

Characteristics of Horizontal Tank Welder:

1. KA-H10 can achieve vertical welding, horizontal welding, circumferential seam welding and other welding.

2. Linear swing function: the swing mode, swing amplitude, swing speed, center position and the left, right residence time can be adjusted.

3. Digital display car running speed.

4. In order to prevent the phenomenon of undercut and welding, the control function of the left and right swing stopping time is set up.

5. Automatic stopping function: when the torch welding stop, it can automatically revert to the weld center.

7. Current and voltage regulation function and point to move the wire function are available.

8. Quick return stroke function.

9. Standard configuration to provide 1.8m long track. Miniaturization ensures facilitative move, extending the use of docking.

Advantages of Horizontal Tank Welder:

1. Reducing the labor intensity and improving the working environment.

2. Work efficiency is 1.5 times of manual welding.

3. Avoiding the bad weld quality caused by human factors (generally non-performing rate of manual operation in about 20%), while the use of automatic welding trolley without resulting in the rate of bad welding.

4. Its comprehensive benefits improved nearly 200% compared to manual welding.

5. The high degree of automation ensures the stability of welding quality.

6. Don’t need skilled technical workers.

Instruction of Automatic Welding Trolley:

1. The DC motor power device of car running. Power supply using AC220V.

2. The track: flexible track, there is a rebound, the standard configuration is 2 meters, can extend the use of docking.

3. The installation guide: magnet track fixing device. The suction can produce 60Kg, can be firmly adsorbed on the workpiece. With a detachable handle, easy to disassemble and move track.

4. Control panel: central control of the car, all the movements are under control.

5. The clutch device: trolley track wheel clutch device. When mounting, the handle is screwed to drive the track wheel to open. and when the track wheel is locked on the track, the handle is loosened automatically. When the handle is in a half clutch state, the quick return stroke function can be realized.

6. The X-Y fine-tuning slider is used to adjusting mechanism of the torch position. X direction of the adjustment range is 20mm, Y direction of the adjustment range is + 20mm.

7. The swing motor (swing head): drive swinging device. Using high precision DC motor, its power is 6W.

8. The welding torch clamp: welding gun clamping device. It can adjust the welding angle, adjusting range of plus or minus 90 degrees.

Control of Horizontal Tank Welder

1.”Welding and non welding” switch: Select “welding” switch, the car in the ready state, press the “start” switch, then welding processing. Select “non welding”, press the” start “button, the car only walk but not for welding.

2. The “start” switch: turn on switch, the car began to walk, then if the car at the “welding” position, welding is started. If at “non welding” position, only a small car to walk but not for welding.

3. The “stop” button: press the stop switch, the car will stop all actions.

4. The walking direction selection switch: either upward or downward to walk.

5. Walking speed: speed value with digital display, maximum walking speed of 1040mm/min, digital display value is 999.

6. The current regulation knob: clockwise rotating with current increases, the scale indicates the value, maximum scale value is 500.

7. The voltage adjusting knob: clockwise rotating with voltage increases, the scale indicates the value, the maximum scale value is 48.

8. A switch: pressing the switch, during the time of wire feed process.

9. Swing speed adjustment knob: clockwise rotating with swing speed increases, the maximum value is 1520mm/min. With the scale, the largest scale of 10.

10. Swing range adjustment knob: clockwise rotating with swing amplitude increases, the maximum value is 20mm. With the scale, the largest scale of 10.

11. Stop time adjustment knob: adjust range is 0 to 2S, clockwise increases.

12. The right stop time adjustment knob: range is 0 to 2S, clockwise increases.

13. Center movable adjustment knob: when clockwise rotation, center is shifted to the right, when anti-clockwise rotation, center is shifted to the left, and moving maximum range is ± 5mm. The maximum scale value is 5.

14. The choice of swing mode knob: use this knob to select the swing mode. There are five car’s swing mode, in addition to the first that is non swing mode, the rest are as follows:

![]()

Parameter of Horizontal Tank Welder:

| Item | Detailed | Remark | |

| POWER | AC 220V, 50/60Hz | ||

| SIZE | 500 × 355 × 243 | W × L × H | |

| WEIGHT | 16KG | ||

| DRIVE | Gear | ||

| Move speed | 0 to 1040mm/min | Digital display | |

| Torch adjust | UP DOWN | ±20mm | |

| Front Back | ±20mm | ||

| Angle | 360° | ||

| Move angle | ±90° | ||

| Rail | Install | Detachable magnet | |

| Size | 42 × 29.3 ×1800 | W × H × L | |

| Material | Belt | ||

| Weight | 20kg | Magnet | |

| Swing | Swing |  |

|

| Speed | 0 to 1520mm/min | ||

| Size | ±20mm | ||

| Time | 0 to 2s | ||

| position | ±5mm | ||

Tags: Tank Welder, Automatic Welding Machine, Horizontal Tank Welding Machinery, Horizontal Tank Welding Equipment